CNC Machining – An Overview of the CNC Machining Process

Table of Contents

What Is CNC Machining?

CNC machining is a manufacturing process in which pre-programmed computer software dictates the factory’s movement of tools and machines. The method can control several complex machines, from grinding machines and lathes to mills and milling cutters. With CNC machining, three-dimensional cutting tasks can performed in a single set of prompts.

How Does CNC Machining Work?

When a CNC system activated, the desired cuts are programmed into the software and dictated to the appropriate tools and machines, which, like a robot, perform the specified dimensional tasks.

In CNC programming, the number system’s code generator often assumes that the mechanisms are error-free despite the possibility of errors. This is greater when a CNC machine instructed to simultaneously cut in more than one direction—a tool in a numerical control system described by a series of inputs known as a part program.

Programs with punch cards entered with a numerical control unit. In contrast, programs for CNC machines sent to computers via small keyboards. The CNC programming stored in the memory of a computer. The code itself is written and edited by programmers. Therefore, CNC systems offer much more computing capacity. Best of all, CNC systems are by no means static as new prompts can add to existing programs with revised code, added Cut My Plastic which is selling acrylic sheets cut to size.

CNC Machine Programming

In the CNC, machines operated by numerical control in which a software program provided for controlling an object. The language behind the CNC machining alternatively referred to as G code. It used to control a corresponding machine’s various behaviors, such as speed, feed, and coordination.

CNC machining enables the machine tool’s speed and position to be pre-programmed and executed in repeatable and predictable cycles by the software without the operator needing anything. Because of these skills, the process has been used in all areas of the manufacturing industry and is particularly important in metal and plastics production.

First, a 2D or 3D CAD drawing is created, then translated into computer code for execution by the CNC system. Once the program entered, the operator will run it on a trial basis to ensure no coding errors.

Open/Closed-Loop Machining Systems

An open or closed-loop system determines position control. The signaling only runs in one direction between the controller and the motor with the former. With a closed control loop, the controller can receive feedback, enabling error correction. Therefore, a closed-loop system can correct for speed and position irregularities.

In CNC machining, the movement generally guided through the X and Y axes. In turn, the tool positioned and guided by stepper motors or servo motors, which emulate the exact movements determined by the code. G. When the force and speed are minimal, the process can carried out by control. Everything else requires regulation to ensure the speed, consistency, and precision required for industrial applications like metallurgy.

In CNC machining, the movement is generally carried out via the X and Y axes.

CNC Machining is Fully Automated

In today’s CNC protocols, the manufacture of parts mostly automated by pre-programmed software. A particular part’s dimensions are determined using Computer-Aided Design (CAD) software and then converted into an actual final product using Computer-Aided Manufacturing (CAM) software.

Different machine tools may required for each workpiece, e.g., B. Drills and Mills. Many of today’s machines combine several different functions in a single cell to meet these requirements. Alternatively, an installation can consist of several machines and a set of robotic hands that transfer parts from one application to another, but all controlled by the same program. Regardless of the setup, the CNC process enables consistency in parts manufacturing that would be difficult or impossible to replicate manually.

The Different Types Of CNC Machines

The first numerical control machines date back to the 1940s when motors were first used to control the movement of existing tools. As technology advanced, the mechanisms with analog and ultimately digital computers have improved, which has led to the increase in CNC machining.

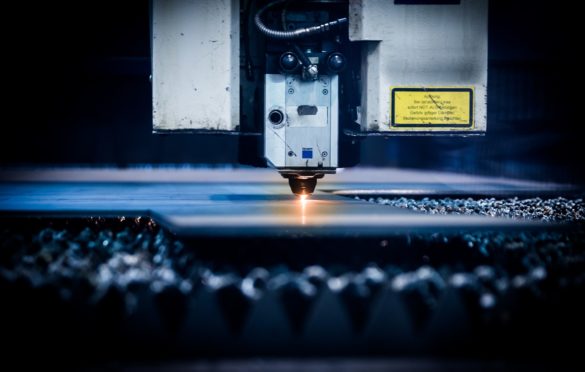

The vast majority of CNC arsenals today are entirely electronic. Some of the most common CNC operated processes include ultrasonic welding, drilling, and laser cutting. The most common machines used in CNC systems include the following:

CNC Mills

CNC milling Machines can work with programs that consist of prompts based on numbers and letters that move parts over various distances. The programming used for a grinding machine could be based on G-code or a unique language developed by a manufacturing team. Basic mills consist of a three-axis system (X, Y, and Z), although most newer mills can accommodate three additional axes.

Some of the most common CNC operated processes include ultrasonic welding, drilling, and laser cutting.

Lathes

In lathes, parts are cut circularly with indexable cutting tools. With CNC technology, the cuts used by the lathes made with precision and high speed. CNC lathes used to make complex designs that would not be possible in manual versions of the machine. In general, the control functions of CNC lathes and mills are similar. As with the first, lathes can powered with G-code or unique proprietary code. Most CNC lathes, however, have two axes: X and Z.

Plasma Cutter

With a plasma cutter, the material is cut with a plasma torch. The process mainly used on metallic materials, but can also be used on other surfaces. To generate the speed and heat required to cut metal, plasma is created using a combination of compressed air gas and electric arcs.

Electric Discharge Machines

Spark erosion (EDM), also known as sink and spark machining, is a process in which workpieces are shaped into specific shapes using electrical sparks. During erosion, current discharges occur between two electrodes, as a result of which sections of a specific workpiece are removed.

As the space between the electrodes becomes smaller, the electric field becomes more intense and therefore stronger than the dielectric. This allows a current to flow between the two electrodes. As a result, each electrode removes parts of a workpiece. EDM subtypes include:

- Wire EDM, where EDM used to remove parts of an electrically conductive material.

- Immersion EDM, in which an electrode and workpiece soaked in dielectric fluid to form the part.

In a process known as scrubbing, the residue from each finished workpiece carried away by a liquid dielectric that occurs when the current between the two electrodes stops and intended to remove additional electrical charges.

Water Jet Cutter

In CNC machining, water jets are tools that cut hard materials like granite and metal using high pressure water applications. In some cases the water mixed with sand or some other strong abrasive substance. Factory machine parts often formed using this process.

Water jets used as a cooler alternative for materials that cannot withstand the intense heat processes of other CNC machines. As such, water jets used in a variety of sectors, including the aerospace and mining industries, where the process is powerful for carving and cutting purposes, among other things. Water jet cutters also used for applications that require very intricate material cuts, as the lack of heat prevents changes in the intrinsic properties of materials that can created by cutting metal on metal.

What Else Can A CNC Machine Do?

As shown in numerous video demonstrations of CNC machines, the system used to make highly detailed cuts of metal parts for industrial hardware products. In addition to the above machines, other tools and components used in CNC systems include:

- Embroidery machines

- Wood routers

- Wire-bending machines

- Turret punchers

- Foam cutters

- Laser cutters

- Cylindrical grinders

- 3D printers

- Glass cutters