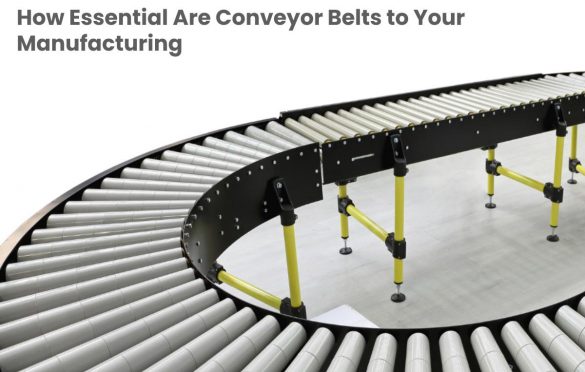

How Essential Are Conveyor Belts to Your Manufacturing Business?

Table of Contents

Conveyor Belts

Conveyor Belts – The short answer would be, ‘very,’ but this is hardly an illuminating answer. Conveyor belts have long been a staple of manufacturing from food and beverage to advanced aeronautical facilities.

Finding the right make, model and style is highly dependent on the nature of your business, as there are almost as many options as there are materials for them to transport.

If you felt like you might need to install some conveyor belt systems around the factory, commercial kitchen or just about wherever you can fit them in your business, here are some reasons why they are not to be underestimated.

A Tremendous Time Saver

Anyone who has ever had to move countless scrap materials around the factory floor will have likely wasted a great deal of time.

Installing a conveyor belt system can negate the need for your employees to come into contact with harmful raw materials and prevent them from having to physically strain themselves from constantly lifting heavy objects. However, employees should still be wearing basic safety equipment such as helmets, goggles, and gloves (you can order your arc-flash gloves today at the Unigloves website) in order to keep themselves safe.

Custom Solutions for Conveyor Belts

There are many custom solutions available, so if you happen to be worried about whether or not your conveyor belt system will be the right fit for your company, there is no need to panic.

In fact, bespoke solutions are incredibly common, and since manufacturing is so diverse in nature, there are many different options worth exploring, so you might want to take a look at fluentconveyors.com for a prime example.

For anyone who needs to transport awkward materials, a custom conveyor belt solution may be better than getting your employees to take on the task of transportation around the factory, particularly if you need to ensure that they practice safe handling.

Health and Safety

In many instances, manufacturing businesses need their employees to work closely with hazardous materials, such as harmful chemicals, sharp and heavy metals, or even toxic fumes emitted from production processes.

These are just about of the reasons why health and safety should be a top priority, factors that a conveyor belt can help you out with.

Installing a conveyor belt system can negate the need for your employees to come into contact with harmful raw materials and prevent them from having to physically strain themselves from constantly lifting heavy objects.Our arc flash gloves are insulated electrical safety gloves. Protect yourself when working with switchboards, power cabinets, or anytime.

Reducing the Cost of Labor

If you utilize production lines throughout your manufacturing business, conveyor belts are a must.

They can effectively reduce the cost of labor by reducing the time taken between stages in the process. If your employees do not need to move around the facility very often, your production time will drastically speed up, which in turn, enables you to maximize the effectiveness of your staff.

Cleaning Materials for Production

Conveyor belts have many more applications than simply transporting goods from A to B. For example, they can work as filters that enable you to sort and potentially even clean your material on the way to production.

Filter belts can drain unwanted or excess fluid from materials, reducing the amount of maintenance and direct human input required throughout the process.

No matter how small or large workspace happens to be, it is likely worth checking out conveyor belt systems, particularly if you aim to optimize your operation sooner rather than later.